Business Sectors

- Home

- Business Sectors

Demonstrating pioneering technological expertise

in business sectors with excellent growth potential

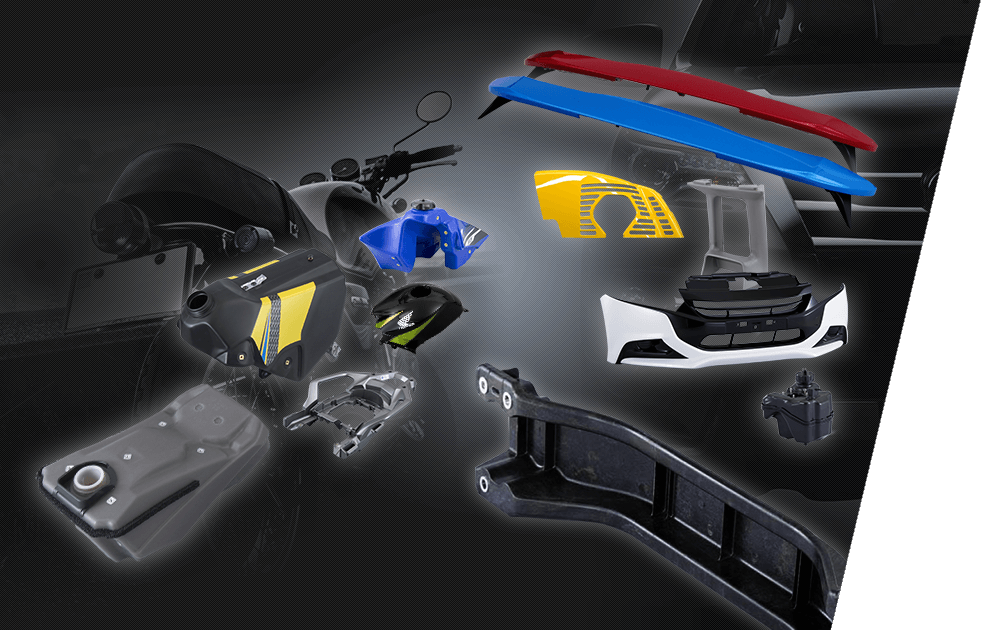

Automotives

Takagi Seiko ventured into one of Japan’s key industries, the automotive sector, in 1957.

Since then, we have repeatedly introduced revolutionary products and technologies, including the introduction of rotational molding for the gasoline tanks of motocross bikes and stylish motorbike cowlings capable of withstanding high engine temperatures, as well as being the first in Japan to use RIM molding technology that enables the single- piece molding of large items such as car bumpers.

Takagi Seiko continues to have success in creating a wide range of car parts in plastic, maintaining its pioneering role in the industry.

- Fuel Tanks

- Spoilers

- Cowlings

- Exterior parts for cars

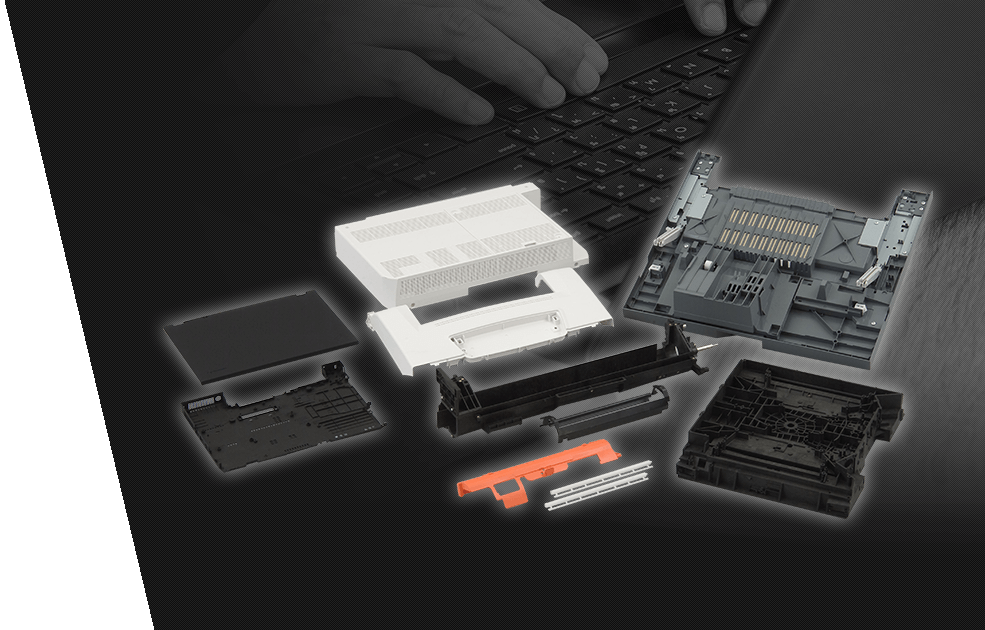

Office Automation

Since the 1980s, the market for office automation equipment such as computers, printers, photocopiers, and fax machines has seen explosive growth.

Takagi Seiko has been meeting a diverse range of needs associated with the plastics found in these products, from external covers and parts to internal plastic mechanisms.

The demands made on these plastic products continue to increase in sophistication each year, with greater standards of dimensional precision and shapes increasingly informed by an emphasis on design.

Despite these demanding market expectations, Takagi Seiko continues to meet these challenges through our successful mass production of a range of specialized injection molding techniques.

- Mechanisms/exterior parts for photocopiers

- Mechanisms/exterior parts for printers

- Notebook computer cases